compression force deflection test|rubber compression force calculation : companies Compression force testing refers to the measurement of push forces acting upon an object. It is a useful method in quantifying the function .

Fotos de las acompañantes. Modelos profesionales. Trato d.

{plog:ftitle_list}

web1 de jul. de 2006 · Dr. A. Jerome ( CPSO# 84284 ) Business Address: 602-2319 Fairview St Burlington ON L7R 2E3 Phone Number: 905-635-3632 Specialties. Specialty Issued On Type; Family Medicine: Effective:07 Jan 2010 : CFPC Specialist: Terms and Conditions (1) Dr. AMANDA LEE JEROME may practise only in the areas of medicine in which Dr. .

Compression testing involves subjecting a material specimen or product to a controlled compressive force until it deforms or fails. The test can be either force- or strain-controlled and can follow either a constant ramp, a fixed waveform, or a random waveform.Compression force testing refers to the measurement of push forces acting . Compression force deflection (CFD) is a common term in the rubber foam and sponge industry – it’s available on most datasheets, it has a defined ASTM testing procedure, and it is one of the best ways to characterize .

Rogers uses Compression Force Deflection (CFD) to represent the firmness of its foam products. Both measurements are common within the gasketing industry and are based on .The compression deflection test can be described as follows: Force required to compress a standardized test specimen 25% of its height. Results expressed in kilopascals (KPA) or . Compression force testing refers to the measurement of push forces acting upon an object. It is a useful method in quantifying the function .Compression Force Deflection, measured in pounds per square inch (PSI), is an accurate test method to measure the firmness of a material at varying compressive levels — a true representation of performance as an ejector in an .

Compression deflection measures the force required to compress a known surface area over a controlled distance. In simpler terms, it is the force that the foam exerts back when in a compressed state. As you might imagine, this .

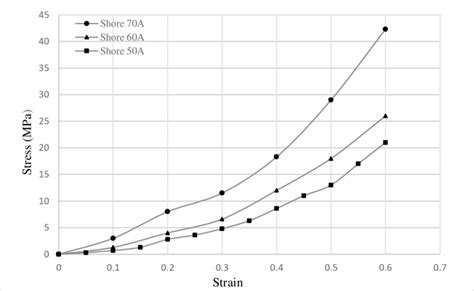

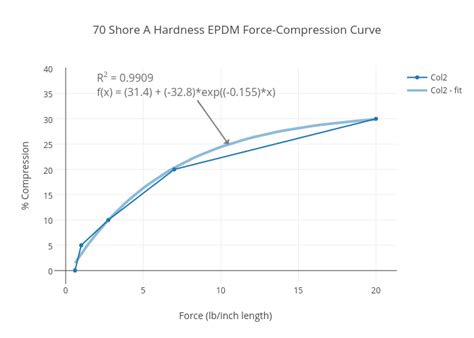

shore hardness vs compression ratio

Compression force testing is a mechanical process that determines the behavior of materials when a compressive or “crushing” load is applied. The most common objectives of .For example, the furniture, automotive, and mattress industries follow ASTM D3574, which measures the indention force deflection of polyurethane foam. This test measures the initial softness of the foam by measuring the force when the .Compression testing is a type of mechanical testing that involves applying a compressive force to a material and measuring its response. The compressive force tends to reduce the size of the material, and the test is designed to . You may hear the term CFD thrown around quite often when talking about elastomeric materials, but do you really know what it means? Rogers Corporation is her.

Universal testing machine used in indentation force deflection test. A Universal Testing Machine (UTM), also known as a universal tester, materials testing machine, or tensile testing machine, is a crucial piece of equipment in the field of material science and engineering. It’s versatile enough to perform various types of mechanical tests, including indentation force deflection.

rubber durometer vs compression force

ASTM D3574 Test C and ISO 3386 both measure the force deflection properties of flexible polyurethane foam at a constant test speed, or rate of extension (CRE). The test is setup to measure the force required to .Deflection data can be obtained from compressive loading, thus from test types such as compression testing, shear testing, bend testing, and cyclic testing. A force-deflection curve is generated using data from the force transducer (load cell or .

When determining the indentation hardness according to ASTM D3574, a distinction is made between the two methods B 1 and B 2: . Objective, applications and results of methods B 1 and B 2:. ASTM D3574 test B 1 Indentation Force Deflection (IFD) is described as an IFD test in which the force is measured, which is required to create certain indentations in foam with a specified .

Test C - Compression Force Deflection Test *Most Common; Test D - Constant Deflection Compression Set Test; Test E - Tensile Test; Test F - Tear Resistance Test; While static tests provide valuable information regarding the initial foam properties and limitations, long-term dynamic testing provides manufacturers insight into the durability of . Compression strength is evaluated through a test called Indentation Load Deflection (ILD), also known as Indentation Force Deflection. This is a computer controlled performance evaluation, with standardization allowing all materials tested using this process to be measured against each other on a balanced plane.

Measuring the compressive strength of a steel drum. In mechanics, compressive strength (or compression strength) is the capacity of a material or structure to withstand loads tending to reduce size (compression).It is opposed to tensile strength which withstands loads tending to elongate, resisting tension (being pulled apart). In the study of strength of materials, .of variance in the test results. The first source was changing loads; as the loads or total deflection changes, values on the force-deflection curves also change. The result is that, if 2 different loads are chosen to test identical seals, values common to both force-deflection curves produced will not be equal.Download scientific diagram | Compression Force Deflection (CFD) test results (ASTM D 3574) of 20 wt.% lignin-based foams and control. Note: Orange bar represents the control foam without lignin.

Differential Thermal Analyzer vendor

For most applications a range between 5% to 15% deflection is acceptable. However, applications with rapid continuous deflection may need to be limited to lower deflection percentages. We recommend not exceeding 25% deflection regardless of the application.The test procedure below follows the publication’s listed compression ratios, but many users pick the rates that are important to their testing. A universal tensile testing machine is needed to complete the test procedures. Force capacities at the two deflection points are recorded as well as the support factor and original thickness.

Test C, known as the compression force deflection test, is utilized to identify the amount of force essential to produce a 50% compression more than the entire area of a sample. This article outlines an example in which all three tests are performed on polyurethane foam. Instrument and Fixtures. The test configuration is displayed in Table 1. Test setup. In the bending flexural test, a specimen is loaded under uniaxial bending stress (tension and compression) in order to obtain information on the bending behaviour of materials.Especially brittle materials such as hard metals, tool steels and grey cast iron are tested in flexural tests. In such a bending test flexural strength, deflection at fracture .Indentation Force Deflection (IFD) tests measure firmness of flexible polyurethane foam cushions. High IFD test results imply increased hardness. Low IFD results indicate soft foam products. Note that the term IFD, or indentation .

Indentation Force Deflection (IFD) test on Polyurethane (PU) foam. Custom test influenced by ASTM D3574. Read our article about ASTM D3574: https://www.adme. This video shows how an ASTM D1056 compression deflection test is performed on an ADMET eXpert 7601 universal testing machine. Click more about ASTM D1056 te.hardness of the surface of the test sample. CFD Compression Force Deflection is a method that compresses the entirety of a material sample (generally about 10 cm) and records the amount of force (stress) that the sample exerts at different levels of compression strain. This allows a more exact determination of firmness at differentASTM D575 test method A is a procedure for determining the compression-deflection of rubber compounds (except hard rubber and sponge rubber). ASTM D575 is useful in comparing stiffness of rubber materials in compression. They can be used by rubber technologists to aid in development of materials for compressive applications. ASTM D575 test method A is a .

Carbon Black Content Tester vendor

Compression Load Deflection Testing is one of the services we offer as part of our physical property tests. It is a non-destructive method for determining the relationship between compressive load and deflection under load for vulcanized rubber. (ASTM D-575). This is useful in determining how a rubber covering will perform in a process condition.ASTM D 3574 Test B1 Indentation Force Deflection (IFD) 压陷硬度 IFD(也称为“ILD”)是确定承载能力(牢固性或刚度)的一种测试方法,以泡沫的特定百分比变形时每50平方英寸磅力表示。 Two of those characteristics or properties are compression deflection and compression set. Compression deflection is a measure of a materials resistance to force applied to a known surface area over a controlled distance. Compression set is the residual amount of deformation of a material after removal of a compression stress.Compression Test Execution: . INDENTATION TEST. Indentation Force Deflection (IFD) is used to characterize the cushioning or compressive properties of a material, especially foams and soft polymers. See more. FRACTURE TEST. Fracture toughness is a material's ability to resist crack propagation. This property is vital for assessing a material .

The deflection realistically should not begin until the free height is reached, as this will provide the most accurate force deflection profile possible. Within the Test Profiler workflow in Bluehill Universal, an initial “Ramp to Free Height” step is utilized in order to reach the preload value. At the conclusion of this step, a variable .ISO 3386-1 - Lower Density Materials ISO 3386-1 covers materials with a density up to 250 kg/m3. It also indicates a method for the calculation of the compression stress value of such materials. The compression stress/strain characteristic is a measure of the load-bearing properties of the material. Two formulas allow the results to be calculated. ISO 3386-2 - High .Finally, the grade rating is determined by the compression deflection given in PSI at 25% deflection. Unlike ASTM D3574, the sample for compression deflection testing for D1056 is much smaller. Solution: Compression Platens with a spherically-seated joint are required to perform these indentation force deflection (IFD) tests. Flexible cellular .

Compression deflection is typically measured using a compression test, where a known force is applied to the foam PSA material, and the resulting deformation is recorded. ASTM D1056 is a standardized test method for measuring the compression deflection of cellular elastomeric materials. This test provides valuable data on the material's .

rubber compression force calculation

Cuteness é um termo subjetivo que descreve um tipo de atratividade comumente associada à juventude e à aparência, bem como um conceito científico e modelo analítico em etologia, introduzido pela Konrad Lorenz.

compression force deflection test|rubber compression force calculation